Carbide nozzle

Filters

Color

Clear

roll up

Density

Clear

roll up

Effect

Clear

roll up

57 bought

NEW

ID: 16484

150 ₽

46 bought

NEW

ID: 17956

150 ₽

10 bought

NEW

ID: 21536

150 ₽

5 bought

HIT

ID: 21822

150 ₽

6623 bought

ID: 3678

280 ₽

3318 bought

ID: 3688

500 ₽

2025 bought

ID: 12595

143 ₽

-5%

2293 bought

ID: 1863

333 ₽

-5%

1473 bought

ID: 11773

190 ₽

-5%

71 bought

ID: 13093

51 ₽

-15%

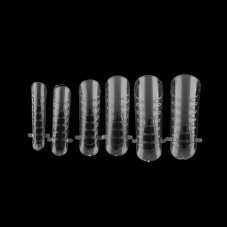

A carbide nozzle is an essential tool for various applications, including milling cutters and nail extensions. It is a high-performance nozzle made of carbide material, which is known for its durability, toughness, and resistance to abrasion and corrosion. Carbide nozzles are ideal for use in harsh conditions that require high-pressure output and long-lasting performance. One of the key advantages of carbide nozzles is their ability to handle high-pressure applications. They can deliver high-velocity, high-volume streams of water, abrasive or other materials, making them ideal for use in cutting, cleaning, or surface preparation tasks. Carbide nozzles have adjustable spray patterns, allowing users to control the intensity and direction of the flow. Carbide nozzles are also highly resistant to wear and tear, making them ideal for use in tough environments. They can withstand the rigors of heavy-duty applications that involve abrasive materials, extreme temperatures, and moisture. In addition, carbide nozzles can last up to 10 times longer than nozzles made of other materials, making them a cost-effective solution in the long run. Carbide nozzles are commonly used in milling cutters, which are machines used to remove material from workpieces. The nozzle delivers the cutting fluid, which lubricates and cools the cutter, making it possible to increase the speed and feed rate. Carbide nozzles can withstand the intense heat generated by the milling process, ensuring that the cutting fluid remains effective. Another common application for carbide nozzles is nail extensions. Nail technicians use these nozzles to apply acrylic or gel nails to customers quickly and efficiently. The carbide nozzle delivers the acrylic or gel onto the nail surface, allowing for precise application and consistent results. Carbide nozzles are also ideal for cleaning nail extensions, as they can remove debris and residue without damaging the nails. In conclusion, carbide nozzles are durable, versatile, and high-performing tools that are essential for a wide range of applications. Whether you're working with milling cutters or nail extensions, a carbide nozzle can help you achieve better results in less time. With its ability to withstand high pressures and harsh conditions, a carbide nozzle is a valuable investment for any business or individual looking to improve their performance and efficiency.