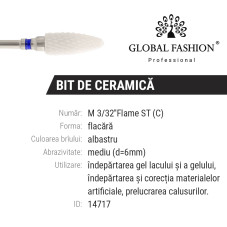

Ceramic nozzles have become an essential part of various industrial and manufacturing operations. These nozzles are designed to withstand extreme temperatures and harsh chemicals, making them ideal for use in applications such as sandblasting, metalworking, and milling.

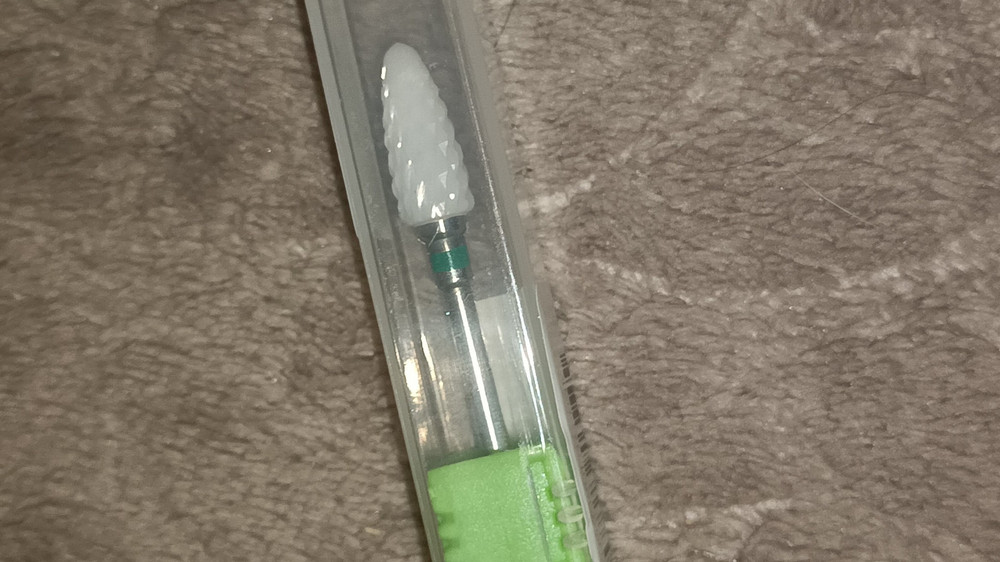

One such ceramic nozzle that has gained popularity in recent years is the H 0615 TB-C. This nozzle is specifically designed to be used with milling cutters, which are used to shape and smooth surfaces on various materials. The H 0615 TB-C is made from a high-quality ceramic material that provides exceptional durability and resistance to wear and tear.

This ceramic nozzle features a unique design that allows for precise and efficient milling. The nozzle has a tapered shape that helps to direct the flow of air and abrasive materials to the exact spot where it is needed. This ensures that the milling process is uniform and consistent, resulting in a high-quality finish.

The H 0615 TB-C ceramic nozzle is also equipped with a special anti-static coating that helps to prevent the buildup of static electricity. This is important in milling operations where static electricity can cause damage to sensitive components or even cause a fire. The anti-static coating eliminates this risk, making the milling process safer and more efficient.

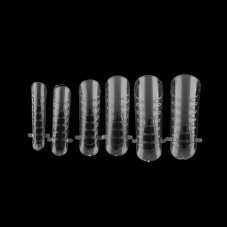

Another notable feature of the H 0615 TB-C ceramic nozzle is its compatibility with a range of milling cutters. The nozzle comes with different nozzle sizes and shapes, allowing it to be used with various cutter types and sizes. This makes it a versatile tool that can be used in various milling operations.

In conclusion, the H 0615 TB-C ceramic nozzle is a high-quality tool that is essential for any milling operation. Its unique design and robust construction provide exceptional durability and performance, making it a reliable tool for various industrial and manufacturing applications. Its compatibility with different milling cutters and anti-static coating makes it a versatile and safe tool for any milling operation.

Product review video:

Product review video: