A cutter cleaning brush is an essential tool for any professional who uses cutting machines, such as milling cutters, on a regular basis. These devices are used to clean the nozzle of the machine to ensure that it is free from debris and other contaminants that may hinder the effectiveness of the machine. The brush is designed to remove even the smallest particles of debris that could lead to a malfunction of the machine.

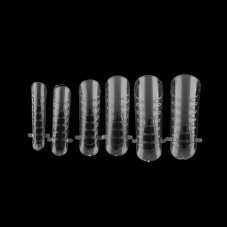

There are different types of cutter cleaning brushes available in the market, with the double brush being one of the most popular options. A double brush has two bristle types, including brass and plastic. The brass bristles are stiff and ideal for removing stubborn debris from the nozzle, while the plastic bristles are gentler and perfect for lighter cleaning needs.

The use of an adhesive-based brush is highly recommended for cleaning nozzles that require more than just brushing. The adhesive on the brush helps to remove stubborn dirt and debris that cling to the nozzle's walls, making it an effective solution for heavy-duty cleaning needs.

Proper use of a cutter cleaning brush is critical to maintaining the effectiveness of the cutting machine. The nozzle should be cleaned regularly, ideally after every use, to prevent the build-up of debris that can cause malfunctions or even damage the cutting machine. When cleaning, turn off the machine and disconnect it from the power source to avoid accidents.

In conclusion, a cutter cleaning brush is an essential tool for effective cutting machine maintenance. The double brush (brass and plastic) and adhesive-based brushes are highly recommended for their effectiveness in removing stubborn debris from the nozzle. Regular use of the cutter cleaning brushes ensures that the machine is always in good condition and functioning optimally.