Drop shape

Filters

Color

Clear

roll up

Density

Clear

roll up

Effect

Clear

roll up

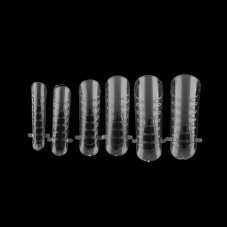

37 bought

NEW

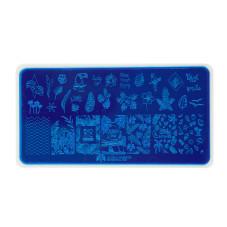

ID: 14627

30 ₽

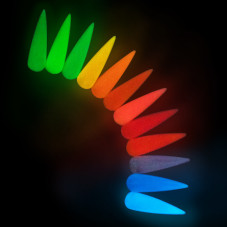

6452 bought

ID: 3678

280 ₽

-20%

3227 bought

ID: 3688

500 ₽

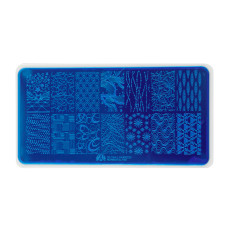

-17%

1515 bought

ID: 1994

280 ₽

-20%

1418 bought

ID: 11773

200 ₽

322 bought

ID: 9034

280 ₽

-26%

168 bought

ID: 12043

200 ₽

-20%

91 bought

ID: 17892

136 ₽

-15%

160 bought

ID: 11958

213 ₽

-15%

87 bought

ID: 15601

170 ₽

-15%

Drop shape is a term used to describe the shape of a liquid drop when it is in a state of equilibrium. This shape is considered to be the most stable and energy-efficient shape that a liquid drop can have. There are several factors that determine the drop shape, including the chemical makeup of the liquid, the surface tension of the liquid, and any external forces acting on the drop. For example, if a liquid is placed onto a solid surface with a low surface energy, the drop will spread out and flatten, producing a larger contact area between the liquid and the surface. Diamond head nozzles for milling cutters widely use drop shape technology. The nozzle shape helps to deliver a precise spray pattern in order to aid in the milling process and increase the tool's lifespan. Diamond milling cutters are incredibly precise, with the ability to create complex shapes and tight tolerances. Drop shape nozzles help to ensure that these cuts are as precise as possible. Drop shape technology is also used in the production of nail extensions. Nail technicians use a small droplet of liquid acrylic to create the shape of the nail. The drop shape is carefully controlled to ensure that the acrylic sets into a smooth, even shape that is both strong and aesthetically pleasing. Technics, a Japanese electronics manufacturer, has also utilized drop shape technology in its turntable design. By carefully designing the shape of the turntable and stylus, Technics was able to minimize vibration and achieve unparalleled playback quality. Overall, drop shape technology is an important concept in many industries, from manufacturing to beauty to audio equipment. By understanding the factors that influence drop shape, professionals can design more efficient and effective products.