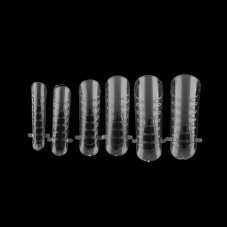

Shape Cylinder

Filters

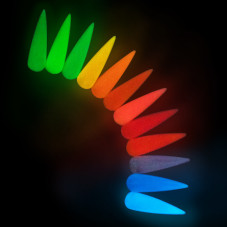

Color

Clear

roll up

Density

Clear

roll up

Effect

Clear

roll up

6452 bought

ID: 3678

280 ₽

-20%

3227 bought

ID: 3688

500 ₽

-17%

1515 bought

ID: 1994

280 ₽

-20%

1418 bought

ID: 11773

200 ₽

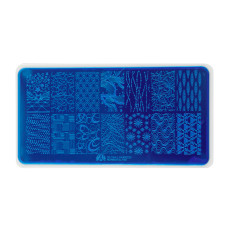

322 bought

ID: 9034

280 ₽

-26%

168 bought

ID: 12043

200 ₽

-20%

91 bought

ID: 17892

136 ₽

-15%

160 bought

ID: 11958

213 ₽

-15%

87 bought

ID: 15601

170 ₽

-15%

Shape Cylinder: Understanding Its Importance in Various Industries A cylinder is a geometric shape that has two parallel, congruent circular bases and a curved surface connecting them. It is a three-dimensional figure that is commonly found in various industries, including engineering, construction, manufacturing, and more. Cylinders come in different shapes and sizes, and their unique properties make them an essential component in a wide range of applications. One of the most crucial factors in the study of cylinders is its shape. The shape of a cylinder determines its functionality in a particular industry. The most common shape is a straight cylinder, which has a constant diameter and height. This type of shape is commonly used in piping systems for transporting fluids, such as oil, gas, and water. The straight cylinder is also used in the construction of buildings and other structures, where they serve as columns and support beams. Another essential shape of cylinders is the tapered cylinder. This shape has a gradually changing diameter from one end to the other. Tapered cylinders are used in industries that require a conical shape, such as the manufacturing of nozzles for milling cutter, diamond head, and nail extensions. In these industries, the tapered cylinder's shape provides precision cutting, shaping, and designing. Apart from the straight and tapered cylinders, there are also other cylinder shapes that serve unique purposes in different industries. The helical cylinder is a shape that has a spiral pattern on its curved surface. It is commonly used in the manufacturing of springs, where the helical shape provides flexibility and elasticity. Another cylinder shape is the stepped cylinder, which has a series of circular bases of increasing or decreasing diameter. This shape is often used for tooling purposes as it provides different sizes of cutting tools. The shape of a cylinder is significant in shaping the function of the cylinder in various industries. The properties of different cylinder shapes can be used to tailor their function and optimize their purpose. The precise shape of a cylinder can significantly impact the functionality of the final application, and as such, requires the utmost attention to detail. It is no wonder that the manipulation and use of cylinder shapes remain a vital aspect of the technics in industries today. In conclusion, understanding the shape of a cylinder is critical in the study of different industries. The shape of a cylinder determines its function and purpose, and as such, requires careful consideration. With this understanding of cylinder shapes, we can use this knowledge to optimize their use and application in various industries. Whether it is for the manufacturing of diamond head, nozzles for milling cutters, nail extensions, or other applications, the shape of a cylinder remains essential in shaping the final product.